Project Name: A Fully Quantitative Treatment Project for Leachate from a Municipal Solid Waste Landfill Site;

Treatment object: accumulated garbage leachate;

Project location: designated by the enterprise or public institution;

Construction unit: enterprise or public institution, limited liability company;

Total treatment capacity of leachate: 1-100000 tons;

Planned completion time for treatment: Complete the full quantification treatment of 10000 to 100000 tons of landfill leachate by the end of a certain year;

Design scale: daily processing capacity ≥ 250m3/d;

1. Main design basis

(1) Other technical documents provided by the owner;

(2) On site research materials;

(3) Law of the People's Republic of China on the Prevention and Control of Water Pollution;

(4) Integrated Wastewater Discharge Standard (GB8978-1996)

(5) Standard for Pollution Control of Domestic Waste Landfill Sites GB16889-2008;

(6) Other policy and technical documents related to the project.

2. Main design principles and solutions

(1) The leachate treatment process must adapt to the treatment requirements of raw water quantity and quality, with mature and reliable process technology and effective control of operating costs.

(2) Strictly follow the relevant environmental protection regulations and discharge standards of the country and environmental protection departments at all levels, and ensure that the effluent meets the national discharge standards without generating secondary environmental pollution.

(3) The leachate treatment process should be selected among the current new technologies, and the selection of process and key equipment must be mature and reliable, with successful operational examples applied to leachate treatment.

(4) According to the existing site utilization conditions, the layout of process equipment should be compact, the logistics transportation should be smooth, and the connection of municipal public works should be convenient.

(5) When selecting equipment, the principle of "energy conservation and consumption reduction" should be implemented, and the process technology should be convenient for operation and management. When designing the factory area, environmental and labor protection measures should be fully considered, and it is best to avoid using measures that affect operation and management personnel

Complex processes with high quality requirements.

(6) The process technology plan should achieve economic and reasonable engineering investment, with relatively low operating costs.

3. Design scope

This design scope is specific to the fully quantified leachate treatment system, including the design of the process plan, equipment composition list, equipment layout design, site condition preparation design, and public engineering supporting design within the treatment system.

4. Analysis of design water quantity, quality, and treatment level

Project scale

This project requires the full quantitative treatment of 10000 to 100000 tons of landfill leachate to be completed by the end of a certain year, and the treatment capacity of the treatment device is designed with a scale of no less than 250t/d.

Design inlet and outlet water quality

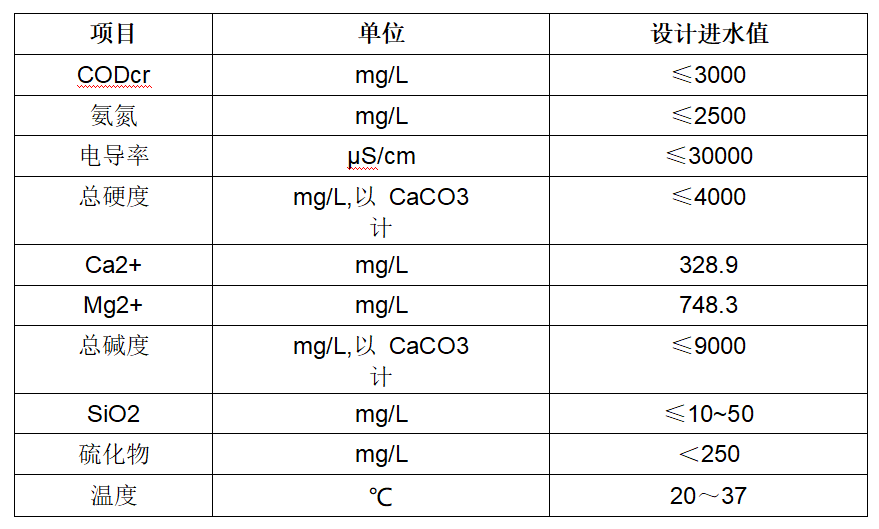

1) Inlet water quality

Note: The indicators in this table are only based on the quality of leachate from similar garbage sites and are for reference only by design and bidding units. Our company will arrange technicians to conduct on-site sampling and retesting, and the specific implementation will be approved by Party A.

2) Design effluent quality

According to the Class 1 A standard in the pollutant discharge standard for urban sewage treatment plants (GB18918-2002). The specific requirements for effluent quality are shown in the table below:

project | unit | limits |

CODcr | mg/L | ≤50 |

BOD5 | mg/L | ≤10 |

Ammonia nitrogen | mg/L | ≤8 |

TN | mg/L | ≤15 |

SS | mg/L | ≤10 |

Discharge direction

1.After treatment, the qualified sewage will be transported by the service provider to the location designated by the owner.

2. The concentrated solution generated by the system is further fully quantified and no concentrated solution is returned to the reactor body.

3. The solidified materials generated by the system shall be transported by the service provider to the location designated by the owner.